Brake Fluid White Paper on Copper

The Use of Dissolved Copper to

Indicate the Age of Brake Fluid

Dean R. Wheeler

Ph.D. in Chemical Engineering,

University of California, Berkeley

March 23, 2006

Introduction

This report, prepared for Phoenix FASCAR, is an

analysis of the chemical changes that take place as

brake fluid is used in service. The report addresses

how the amount of dissolved copper in the fluid can

serve as an indicator of the age and protective

ability of the fluid. The conclusions here come from

my interpretation of experimental data made

available to me, and my professional scientific and

engineering analysis. The references section at the

end gives some of the information sources I used in

preparing this report.

Brake fluid basics

Brake fluid is a hydraulic fluid mixture that

must function under many months of service and under

periodic high-temperature conditions. The main

governmental standard imposed on brake fluid is that

it have a high boiling point so that pockets of

vapor will not form in the braking system under

severe braking conditions. For instance,

moisture-free DOT 3 fluids must have a boiling point

above 400 °F. This can be compared to the boiling

point of 387 °F for pure ethylene glycol (automotive

antifreeze). In fact, many of the molecules that

make up DOT 3 and DOT 4 brake fluids can be

considered “larger chemical cousins” to ethylene

glycol. DOT 3 and DOT 4 brake fluids are

hygroscopic, meaning they will mix with and absorb

water, which lowers the boiling point just like with

antifreeze. This has led many people to incorrectly

believe that a low boiling point caused by water

absorption is the only thing that can go wrong with

brake fluid.

Current automotive brake systems contain steel

components, such as cylinders and valves, connected

by lengths of copper-alloy-lined steel tubing. Both

the steel and the copper components are unavoidably

subject to corrosion. One need hardly mention that

corrosion and wear of the metal surfaces can

interfere with the proper operation of these

components, leading to a diminished margin of

safety. Fortunately, the addition of standard

corrosion inhibitors by brake-fluid manufacturers

significantly slows the corrosion of critical steel

components, leading to much improved service life.

Recently there has been increased attention to

the fact that the protection offered by the

corrosion inhibitors in brake fluid does not last

indefinitely. As brake fluid ages in service, its

chemical constituents undergo a number of changes.

Ordinarily none of these fluid chemical changes are

immediately catastrophic, but cumulatively and over

time they lead to decreased braking-system

protection and performance. As already mentioned,

decreased boiling point (associated with water

absorption) is well recognized as a sign of

brake-fluid aging. However, this is not the complete

picture. As discussed below, an increased level of

dissolved copper in the solution is an important and

reproducible indicator that the brake fluid is no

longer effectively protecting metal surfaces from

corrosion.

The chemistry of corrosion

In order to better understand the changes taking

place in the brake fluid, it is necessary to have a

little background in corrosion science. The main

principle is that rust is a more natural and stable

state of iron than is a shiny machined steel part.

Rust is composed of iron mixed with oxygen.

Similarly, other metals such as copper corrode

spontaneously by reacting with oxygen. In practical

environments it is impossible to fully prevent

corrosion; instead it is a matter of trying to slow

it down as much as possible.

For most metals (gold is a notable exception)

exposed to dry air, a thin layer of the metal on the

surface reacts with oxygen in the air to form a

dense oxide film. This film "passivates" and

protects the rest of the metal by acting as a

barrier to greatly reduce further reaction with

oxygen. Unfortunately, when water or a similar

solvent contacts the metal, it partially dissolves

the protective metal oxide skin, leading to

increased corrosion in the presence of oxygen. The

problem is typically made even worse in situations

where there are aggressive chemicals or high

temperatures present. Note that most of what we know

about metals and corrosion is for the case of water

mixtures; however, the same principles apply to

brake fluid.

A simplified corrosion reaction for a metal in

liquid looks something like this:

metal + dissolved oxygen + acid =

dissolved metal.

There are a few ways to "starve" this reaction

and therefore slow down the corrosion: First, one

can attempt to reduce the amount of dissolved oxygen

in the solution. In the case of brake systems, it is

nearly impossible to prevent oxygen from absorbing

into the solution due to the fluid-air interface in

the master cylinder, and the slow leakage of oxygen

into the system through rubber parts. A second

scheme is to reduce the acid in the system by adding

chemicals that are alkaline. This scheme is used in

brake fluids. A third scheme is to add chemicals to

the system that stick to and coat the metal surface,

providing a barrier in addition to the metal oxide

film to slow things down. This scheme is also used

in brake fluids.

Water is known to degrade the integrity of the

oxide film on metals; however, water is not the only

solvent that can do this. Corrosion can take place

in other liquids, such as those that make up brake

fluid. Furthermore, there is no practical way to

keep brake fluid completely moisture free, so there

will always be some water present near the metal

surface. I am aware of only two scientific studies

of corrosion in brake systems (both are listed in

the references section). Neither showed that the

amount of absorbed water in a brake fluid was a main

controlling factor in how fast the metals corroded.

Corrosion with different metals

There is one more complication I need to

introduce into the corrosion picture, namely that

individual metals differ in their susceptibility to

corrosion and also can corrode one another. This can

work to advantage or disadvantage depending on the

system. Here I consider three metals: zinc, iron,

and copper. Zinc is the least "noble" of the three -

meaning most susceptible to corrosion - while copper

is the most noble. I give some examples of this

metal-to-metal corrosion behavior below.

Galvanized nails used in home construction are

steel nails that have been dipped in molten zinc to

form a zinc coating on the outside. Because zinc is

less noble than iron, it will corrode before iron

will. If the zinc coating is ever broken, and

dissolved oxygen gets to the exposed steel surface,

the surrounding zinc will "sacrifice" itself and

react with the oxygen before the iron does, and thus

protect the iron.

Copper, being the most noble of the three metals

I listed, is the best protected against oxidation or

corrosion under normal exposure to dissolved oxygen.

This is the reason that plumbing pipes in homes are

generally made of copper, not steel. However, in a

situation where copper metal has already been

corroded and dissolved into a liquid, it will attack

any iron metal (steel) it comes in contact with.

This is because, like zinc does for iron, the iron

will sacrifice itself for the copper. The result is

that dissolved copper will come out of solution and

plate onto the surrounding steel, while a

proportional amount of iron will dissolve and go

into solution. While the initial corrosion reaction

of copper requires oxygen and acid, the second

reaction where dissolved copper corrodes the iron

does not have this requirement. This chemistry is

important in explaining what can happen in brake

systems with aged and degraded brake fluid.

The Highway Traffic Safety Administration of the

U.S. government conducted a six-year engineering

analysis (EA94-0038), culminating in a report in

year 2000, to investigate decreased performance and

possible failure of anti-lock braking systems on

light trucks and SUVs. During the course of the

investigation the agency contracted the services of

the National Institute for Science and Technology

(NIST). The scientific tests by NIST indicated that

it was possible for corrosion to take place in the

brake system so as to form deposits of foreign

copper particles around the sealing surfaces of the

steel PWM valve. The effects of a leaking PWM valve

on vehicle braking performance were studied in a

separate report (EA95-026). The important lesson, as

I discuss below, is that copper is not necessarily

benign and inert in the presence of iron and could

lead to degraded braking performance.

The role of corrosion inhibitors in brake

fluid

Corrosion inhibitors come in many varieties, but

the ones used in brake fluid are typically based on

a chemical group called "amine." The amine-based

inhibitors are well known as being able to protect

iron or steel from corrosion in aggressive

high-temperature liquid environments. For instance,

amines are widely used as corrosion inhibitors in

steam boilers. Individual amine inhibitors work in

one of two different ways: (1) by reducing the acid

level (neutralizing or buffering amines) and (2) by

forming a water-repelling barrier film on the metal

surface (filming amines).

In brake fluid, the amount of amines present is

usually reported in terms of "reserve alkalinity," a

scientific term that indicates how much acid can be

added to the brake fluid before the neutralizing

ability of the amines is exhausted. However,

neutralizing amines alone will not

adequately prevent corrosion in the presence of

dissolved oxygen. This is because even in a buffered

alkaline solution (high pH) there is still a small

amount of acid present to slowly feed the corrosion

reaction. To give full protection, the inhibitor

package requires the help of the filming amines as

well. However, reserve alkalinity does not

necessarily account for the presence or absence of

the filming amines, and so gives only a partial

picture of how much protection is left in a given

sample of brake fluid.

A fact that is rarely appreciated is that the

amines do not protect copper as well as

they protect iron. This is backed up by the

observation that dissolved-copper levels in brake

fluid begin rising almost immediately upon the fluid

being put into service, and the levels rise

consistently throughout service. On the other hand,

dissolved-iron levels do not begin to rise

noticeably until the corrosion inhibitors have

already been significantly depleted.

A significant experimental study was conducted

jointly by researchers at Delphi, Union Carbide, and

General Motors and published by the Society of

Automotive Engineers in 1997 (see references

section). The researchers examined the durability of

corrosion protection in brake fluids. They found

that the corrosion protection declined sharply with

time in service. The following numbers are telling:

Reserve alkalinity was between 10 and 20% of its

initial level for the tested fluids after 30 months

of service (about 23,000 miles). Furthermore, they

found that by 40 months of service (about 34,000

miles) most of the amine inhibitors were deactivated

by thermal reactions that turned them into

non-inhibiting chemicals. Interestingly, they found

that around 60% of the amines-both active and

inactive-were lost entirely from the brake fluid by

this time. They believed this to be due to the

amines being volatilized (evaporated) into the air

space of the master cylinder and by permeating out

through rubber components.

The role of dissolved copper in brake

fluid

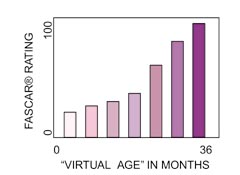

Experiments by both Phoenix Systems and the

industry researchers mentioned above have found that

dissolved copper levels in brake fluid increase

nearly constantly with time of service. The SAE

paper reports copper levels at 150 to 300 ppm (parts

per million) after 30 months of service. In

contrast, the respective levels of dissolved iron

and zinc are significantly smaller and do not follow

as clear of a trend with time. It is true that

dissolved iron could be used as an indicator of a

problem, because elevated levels of dissolved iron

clearly show that corrosion has occurred. However,

this may not be the best practice in a routine

maintenance program that is intended to keep

corrosion low at all times, rather than respond to a

problem after it develops. In summary, copper

concentration level in the fluid is one of the

clearest available indicators of time-in-service for

brake fluid. It can serve like wear indicators on

brake pads do, warning when a problem is imminent

rather than just warning when a problem has already

developed.

Moreover, copper is much more than a benign

indicator of brake-fluid service time. Copper plays

a key role in the chemistry of corrosion for the

brake system. The problem as discussed above is that

relatively unprotected and large copper surfaces can

corrode almost from the outset of fluid service. The

corrosion of the copper-lined tubing is less

worrisome than it is for the moving steel parts in

the brake system, because close tolerances are not

as essential for the tubing. The problem, however,

is that the dissolved copper then goes on to attack

and deposit itself on the steel surfaces once the

corrosion inhibitors are sufficiently depleted. The

presence of high levels of dissolved copper in the

brake fluid indicates that the steel surfaces in the

brake system are already or will soon be under

attack.

The SAE study included an attempt to create

artificially aged braking fluid for testing

purposes. The researchers found that two things were

required to create fluid that behaved similarly to

fluid that had seen many months of vehicle service:

(1) significant amounts of added copper and (2)

elevated temperatures in order to thermally degrade

the corrosion inhibitors. Simple thermal degradation

without adding copper did not lead to fluid

that correctly mimicked the corrosive action of

truly old brake fluid. In fact, the researchers

speculated that the copper metal added to the system

acts as a catalyst to promote the degradation of the

amine-based inhibitors.

My analysis suggests that the presence in the

brake system of copper as well as amine-based

corrosion inhibitors is an unfortunate combination

that in the end works to promote iron corrosion. It

is known that amines associate strongly with

dissolved copper. Any filming amines that associate

with copper in solution cannot at the same time do

their job of protecting iron. Therefore, elevated

levels of dissolved copper may interfere with the

effectiveness of the filming amines in preventing

corrosion of the steel surfaces.

Additional factors in fluid age

There are additional factors that can aggravate

the corrosion problems mentioned above. For

instance, anti-lock braking systems create greater

circulation of brake fluid in the system. This

circulation causes dissolved oxygen and dissolved

copper to transport more freely throughout the

system, likely leading to greater corrosion exposure

that inhibitors must then counteract. This could

lead to more rapid depletion of inhibitors than in a

non-ABS system.

Similarly, city driving with its more extensive

use of braking will lead to elevated temperatures in

the system. Spontaneous chemical reactions always

speed up at higher temperatures. Therefore, higher

temperatures accelerate all of the undesirable

corrosion-both of copper and iron-as well as the

processes that degrade the inhibitor package.

Therefore, an automobile that has seen "hard

driving" with frequent use of brakes is likely to

show greater depletion of the inhibitors and loss of

corrosion protection, as well as greater copper

concentration, for a given time or mileage in

service. So the use of copper concentration as an

indicator will naturally account for some degree of

variation in user abuse of the braking system. On

the other hand, elevated temperatures will tend to

reduce the amount of water that would

otherwise be in the brake fluid. This is because

water, with its lower boiling point, will volatilize

more strongly than other components as temperature

is increased.

Other measurements of fluid age

In contrast to dissolved-copper measurements,

boiling-point and reserve-alkalinity measurements

are less effective as indicators of fluid-service

time. This is because these two quantities can vary

so widely from one manufacturer's brake-fluid

formulation to the next. Unlike in a laboratory

experiment, a technician in the field has no

foolproof way of knowing the baseline level of

either quantity. For relatively new cars it is

reasonable to assume that they contain the

OEM-formulated brake fluid, but for a car that has

been in service for a few years the brake fluid is a

big question mark and could by that point even be a

mixture of different manufacturers' brake fluids.

For instance, the SAE paper notes the wide

variations, with reserve alkalinity levels for fresh

commercial brake fluids ranging from a low of 3 to a

high of 120. These researchers also warn that

reserve alkalinity only measures general

acid-buffering ability and not the concentration of

particular inhibitors. Therefore, it would be

unlikely that one could reliably predict either (1)

months of service of the brake fluid or (2)

remaining strength of the full corrosion-inhibitor

package using boiling point or reserve alkalinity.

References

G.L. Jackson, P. Levesque, and F.T. Wagner,

"Improved Methods for Testing the Durability of

Corrosion Protection in Brake Fluids," Paper 971007,

SAE Technical Paper Series (1997).

R.E. Ricker, J.L. Fink, A.J. Shapiro, L.C. Smith,

and R.J. Schaefer, "Preliminary Investigations Into

Corrosion in Anti-Lock Braking Systems," Internal

Report 6233, National Institute of Standards and

Technology, U.S. Dept. of Commerce (1998). |

![]()