Carbide Brake Lathe Bits

Plus... Brake Lathe Holders and

Conversions

| Parallelogram | HD Thick | Round | OEM | High Radius |

|

|

.jpg) |

.jpg) |

|

.jpg) |

GWR features the

finest "Micro Grain" C3 Carbide cutting bits for all brands of

brake lathes, while the industry standard is only C2 Carbide. We

additionally offer the newest of cutting technologies like

"Round Bits" and our revolutionary "Super Purple PVD Bits".

These special bit designs speed up the cutting process by up to

70%, while reducing rotor roughness (RA) by up to 25% and net

cost per rotor by up to 50%.

|

|

|

|

|

G.W.R....

Specialty Products

features and recommends the finest cutting systems in the industry...

ROUND LATHE BITS...

Cut Rotors Five Times Faster!

The "Original" Round Lathe

Bits

GWR offers the original from 1992, the first and highest quality Round Bit

rotor finishing system in the industry. Because of the exclusive "lock

washer" hold down clamp, there is no equal on the market! A simple

tightening of the screw on the proprietary clamp prevents the bit from

turning or chattering, unlike the other versions being sold through most

parts distributors. The secret is to look at the screw. If it is 90º

(vertical orientation) to the tool holder body... it is the proper design

and will work properly. Unfortunately some OE companies have recently tried

copying this unique design and are causing confusion in the market place.

It's interesting to note that 10 years ago Ammco said "round bits are bad

and would not work". Now they are saying "theirs are just like the ones GWR

sell". Just be careful with the copies! Our holders work and have the exact

design that assures you the finest finishes, easiest changes and longest

life.

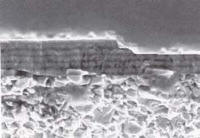

|

Our other

preferred "performance" bit, when you like an original triangle

style configuration..... GWR's

"Super

Purple" Lathe Bitstm

First,

our bit is positive rake! This allows for a finer finish cut

when compared to negative rake designs. Additionally, they will

shave through hard spots, not bump over them. This produces

truer rotors, with less possibility of run out.

|

||||||

Please click this link to see the complete listing of:

| Parallelogram | HD Thick | Round | OEM | High Radius |

|

|

.jpg) |

.jpg) |

|

.jpg) |

| Click Here for All Items |

GWR Specialty Automotive

Products Copyright 1996-2017 1(800) 266-4497 Email: sales@GWRauto.com |

|